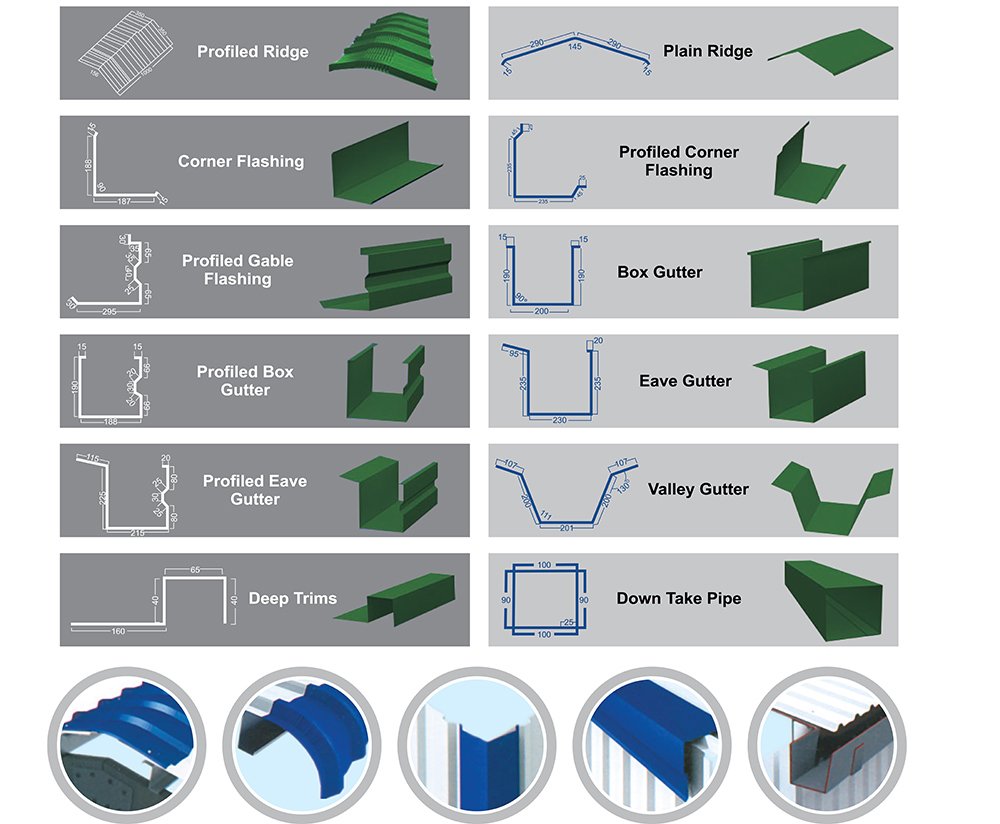

Roofing accessories

Roofing Ridge

| Material | Steel / Stainless Steel |

| Dimensions | 5500*800*1200 |

| Surface Treatment | Coated |

| Technique | Cold Rolled |

| Features | Water Proof |

Features:

- Impeccable finishing

- Durable

- Superior strength

Specifications:

- Sheet Width: 610 mm

Available Colors:

- Off White

- Sky Blue

- Autumn Red

- Grey

- Taurus Blue

- Royal Blue

- Caulfield Green

- Mist Green

Metal Apron Flash

| Features | Water Proof |

| Technique | Cold Rolled |

| Surface Treatment | Galvanised |

| Material | Steel / Stainless Steel |

Features:

- Unmatched sturdiness

- High durability

- Resistant to corrosion

Available Colors:

- Off White

- Sky Blue

- Autumn Red

- Grey

- Taurus Blue

- Royal Blue

- Caulfield Green

- Mist Green

L Flashing

In order to provide utmost satisfaction to our clients, we engage in the utilization of high grade raw materials and modern machines, in compliance with the set industry norms and guidelines, for manufacturing this impeccable range of L Flashing. The offered product is widely acclaimed for its resistance to corrosion, sturdiness, durability and strength. In addition, it is marked at the most reasonable rate possible.

Features:

- Unmatched sturdiness

- High durability

- Resistant to corrosion

Specifications:

- Sheet Width: 610 mm

Available Colors:

- Off White

- Sky Blue

- Autumn Red

- Grey

- Taurus Blue

- Royal Blue

- Caulfield Green

- Mist Green

Corner Trim

Being one of the leading manufacturers and suppliers of this impeccable range of Corner Trim, we never compromise with its quality. Thus we engage in the utilization of high grade raw materials and modern machines, in compliance with the set industry norms and guidelines. Owing to this, the product’s sturdiness, durability, resistance to corrosion and dimensional accuracy is quite high.

Features:

- Unmatched sturdiness

- High durability

- Resistant to corrosion

Specifications:

- Sheet Width: 610 mm

Available Colors:

- Off White

- Sky Blue

- Autumn Red

- Grey

- Taurus Blue

- Royal Blue

- Caulfield Green

- Mist Green

Drip Trim

We are considered in the market to be one of the leading manufacturers and suppliers of this impeccable range of Drip Trim. Manufactured in accordance with the set industry norms and guidelines, its quality never deteriorates. The offered range’s impeccable sturdiness, durability, resistance to corrosion and dimensional accuracy, is owed to the finest that are available in the market.

Features:

- Dimensional accuracy

- Resistant to corrosion

- Commendable finishing

Available Colors:

- Off White

- Sky Blue

- Autumn Red

- Grey

- Taurus Blue

- Royal Blue

- Caulfield Green

- Mist Green

Barge Cap

For reasons of quality maintenance, the offered range of Barge Cap is manufactured as per the set industry norms and guidelines. Owing to this, the offered product is known to have a superior sturdiness, durability and resistance to corrosion. In addition, the offered range is marked at the most reasonable rate possible, making it highly asked for in the market.

Features:

- Unmatched sturdiness

- High durability

- Resistant to corrosion

Specifications:

- Sheet Width: 610 mm

Available Colors:

- Off White

- Sky Blue

- Autumn Red

- Grey

- Taurus Blue

- Royal Blue

- Caulfield Green

- Mist Green

Corner Flashing

| Area of Application | Residential |

| Tensile Strength | 550 Mpa |

| Thcikness | 0.35 -0.50 mm |

| Base metal | High Tensile Steel |

| Type of coating | Regular modified polyester |

| Coating | Az 150 |

| Painting Thickness | 5-20 Microns |

Features:

- Easy to install

- Longer-serving life

- Water Proof

- Tamper Proof

- Corrosion Resistant

- Durable Coating

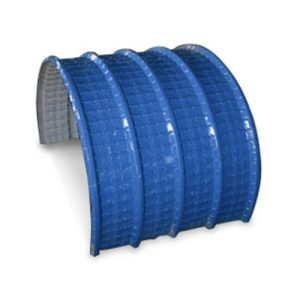

Crimped Sheets

| Surface Treatment | Galvanized, Color Coated |

| Area of Application | Residential |

| Thickness of Sheet | 0.35 – 0.50 mm |

| Material | Stainless Steel |

| Tensile Strength | 550 Mpa |

| Composition | 55% Aluminum, 43.5% zinc & 1. 5% silicon |

| Tolerance | +/-0. 03 mm |

| Top Painting thickness | 18-20 microns |

| Coating | Az 150 |

Features:

- Dimensional accuracy

- Seamless finish

- Longer-serving life

NLC Galvanized Sheet

| Thickness | 0.35 -0.50 mm |

| Color | Red |

| Tensile Strength | 550 Mpa |

| Base metal | High Tensile Steel |

| Application | Commercial, residential |

| Coating | Az 150 |

| Composition | 55% Aluminum, 43.5% zinc & 1. 5% silicon |

Roof Ridges

| Dimensions | 15″ x 10″, 5″ x 3.5″ |

| Surface Treatment | Galvanised |

| Material | Stainless Steel |

| Application | Commercial, Residential |

| Composition | 55% Aluminum, 43.5% Zinc & 1.5% Silicon |

Features:

- Weather resistance

- Easy installation

- Abrasion resistance

Shed Water Gutter

| Dimensions | 15″x10″, 5″ x 3.5″ |

| Surface Treatment | Galvanised |

| Manufacturing Technique | Hot Rolled |

| Material | Stainless Steel |

| Application | Commercial, Residential |

Features:

- High strength

- Easy installation

- Corrosion resistance