Roofing sheet

Roofing sheet

Our Color Coated Corrugated Sheets are manufactured by using Alu-Zinc coated plate (PPGL) as the raw material, combined with a high quality, suatable and economical paint. With imported production lines, we are able to produce adequate amount of steel corrugated sheets as aesthetics, good quality and economical light weight, high strength product to satisfy large scale market demands as well as to model your dream structure. Our Trapezoidal Profile is excellent use for Roofing and Cladding.

Total Coating Thickness (TCT) : 0.4, 0.45, 0.47, 0.5, 0.55, 0.6, 0.65, 1.0 (mm.)

Width: 1060 mm (1.06 mtr.)

Standard Length (Feet): 8, 10, 12, 14, 16 (Customizable upto 30 Feet).

Color: Castle Red, Sky Blue, Asian White, Bright Green, Gray / Light Gray(Back Side)

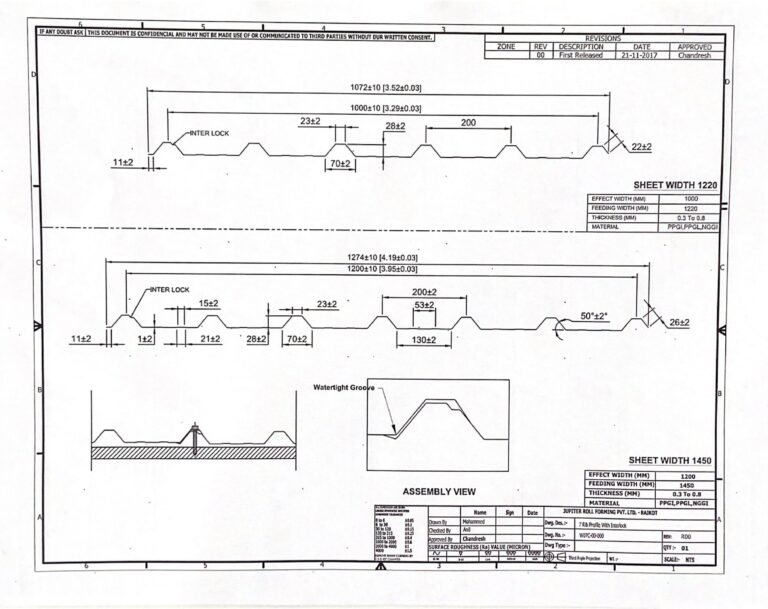

Technical Specifications

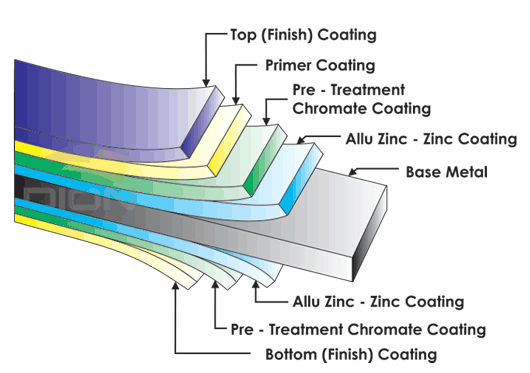

Pre-Painted Alu-Zinc Steel Sheets (Galvalume*): (55% Aluminium, 43% Zinc, 1.5% Silicon) Aluminium – Zinc Alloy coating gives corrosion resistance and superior heat reflectivity, Galvalume Steel reflects a high percentage of heat and can withstand in any weather conditions, without surface discoloration. It is also suited for coastal areas. Bare Galvalume coating is inorganic and does not contain volatile compounds that can harm the environment.

Material Structure

Accessories

The Special waterproof accessory is very important for installation. We need to use the special waterproof accessory to retain the roofing sheet property. To avoid the roofing sheet have unusual circumstance (such as water-leakage, distortion etc.), then effect the lifespan of products.

While installation, always use the waterproof fixing accessory and also recommend to have experienced Fabricator/Worker to install our sheets with the special accessories for better waterproofing, strong wind withstanding and corrosion resistance.

Benefits of Color Coated Sheets

- High Strength

- Superior Heat Resistance

- Good Longevity

- Corrosion Resistance

- High Thermal Reflectivity

- Aesthetically Attrative

- Spectrum of Colors

- Easy to Install

- Economical

- Available with Customise size

Applications of Color Coated Sheets

DION Color Coated Sheets are excellent use for Roofing and Cladding.

- Industrial Sheds (Factory Building & Walling, Industries, etc.)

- Commercial Sheds (Hotel & Resorts, Parking Sheds, Market Sheds, School, Colleges, Shelters, walkways, etc.)

- Domestic Sheds (Residential Building, Vehicle Parking, etc.)

- Agricultural Sheds (Ware houses, Animal houses, Godowns, Farm house, etc.)

| Metalic Coating | Alu-Zinc All Coating AZ150 |

| Paint Coating | Regular Modified Polyster |

| Painting Thickness (Top) | 18-22 microns |

| Painting Thickness (Bottom) | 5-7 microns |

| Surface Paint Reflection | GLossy Finish |

| Standard Followed | ASTM A755, IS277, JIS3322, AS1397 |

| Tensile Strength | 240-550 Mpa |