UPVC roof sheet

UPVC roof sheet

The 3 layer Type Heat Insulated UPVC Roof Sheet is manufactured based on co-extrusion technology by one-time processing. For projects requiring heat insulation, it is an ideal building material. It possesses characteristics such as superior thermal and sound insulation, water resistance and fire corrosion. The following is a list of the distinct features of each layer material.

Jalaram Industries is a professional new enterprise providing complete roofing system in India. The company has ventured into producing uPVC (Unplasticized Polyvinyl chloride) corrugated three layer Roofing sheets popularly known as Plastic Roofing Sheet.

Jalaram Industries uPVC sheets are manufactured at its plant at Shapar-Veraval, a fully developed industrial estate near Rajkot. The manufacturing facility is equipped with latest state-of-the art automated machineries. Enabling us to offer the best quality, uPVC sheets, at the most competitive prices.

Jalaram Industries uPVC sheets are optimum choice for roofing and cladding. uPVC roofing sheets is the best replacement to conventional asbestos, metal G.I. sheets, fiberglass sheets and ceramic tile sheets, considering its property of heat insulation, sound insulation, water resistance, chemical and alkali resistance, corrosion proof, fire retardant, eco friendly. They are easy to install and move, light weight as well as cost effective in installation. Not only that, but it can save construction cost up to 50%.

Special Features

Application

- High-grade plants like corrosive chemical plants and smelters, printing and dyeing plants, etc.

- Factories like soy sauce factories, organic solvent factories, etc.

- Mobile homes

- Factory, warehouses

- Farmers markets

- Sheds

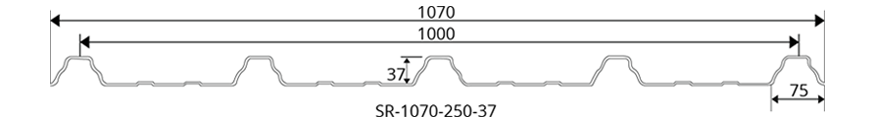

Profile Drawing (SR 1070)

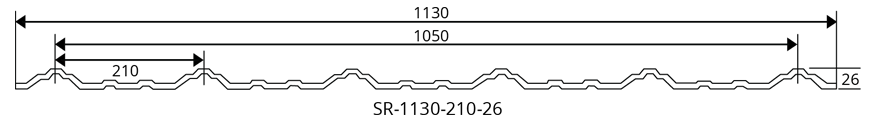

Profile Drawing (SR 1130)

| Thickness | 2.0mm | 2.5mm | 3.0mm | |||

| Length | 5800mm, 11800mm or Customized | |||||

| Total Width | 1130 mm | |||||

| Cover Width | 1050 mm | |||||

| Purlin Span | 700mm | 800mm | 900mm | |||

| Slope | >20. | >20. | >20. | |||

| Container Load Capacity | 20″(21 tons) | 40″(26.5 Tons) | 20″(21 tons) | 40″(26.5 Tons) | 20″(21 tons) | 40″(26.5 Tons) |

| 5600 m2 | 7200 m2 | 4400 m2 | 5600 m2 | 3600 m2 | 4600 m2 | |

| Color Choice | White, Light Yellow, Sky Blue, Light Green, Light Grey or Customized | |||||

| No. | Test Item | Test Method | Test Condition | Test Result |

| 1 | Tensile Strength | ASTM 0638-10 | Testing speed: 50mm/min | 26 Mpa |

| 2 | Flexural Strength | ASTM 0790-10 Procedure | Testing speed: 1.3mm/min Span: 48mm | 52 Mpa |

| 3 | Temperature Different Between Outdoor and indoor | 8 °c | ||

| 4 | Impact Resistance | ASTM 05420-10 | Geometry: GE (012.70mm) Impact Weight: 0.9kg | Mean failure energy: 4J |

| 5 | High Temperature Resistance | 60°c,6h | No Visible change | |

| 6 | Low Temperature Resistance | -35°c,6h | No Visible change | |

| 7 | Chemical Resistance | 70% Ethanol solution,(v/v) , Immersion test, 23°C, 2h | No Visible change | |

| 10% NaOH solution,(m/m), Immersion test, 23°C, 2h | No Visible change | |||

| Saturated NaCL solution, Immersion test, 23°C, 2h | No Visible change | |||

| 8 | Thermal Conductivity | ASTM C518-10 | Mean Temperature 25.48 c / Temperature different 9.36 c | Thermal conductivity: 0.071 [W/(m.K)] |

| 9 | 20mm Vertical burning test | UL 94-20 13 Section 8 | Specimen: 129 x 12.5 x 3.0mm | V-0 |

| 10 | Sound Insulation | Compare with metal roof tile | 30 dB lower |